Mkati mwa njira zogulitsira, amatsenga ena amasandutsa mchenga kukhala ma silicon crystal discs opangidwa ndi diamondi, omwe ndi ofunikira pamayendedwe onse a semiconductor. Ndiwo gawo la semiconductor supply chain yomwe imachulukitsa mtengo wa "silicon sand" pafupifupi nthawi chikwi. Kuwala kocheperako komwe mukuwona pagombe ndi silicon. Silikoni ndi kristalo wovuta wokhala ndi brittleness ndi chitsulo cholimba ngati zitsulo (zachitsulo komanso zopanda zitsulo). Silicon ili paliponse.

Silicon ndi chinthu chachiwiri chodziwika bwino padziko lapansi, pambuyo pa okosijeni, komanso chachisanu ndi chiwiri chodziwika bwino m'chilengedwe chonse. Silicon ndi semiconductor, kutanthauza kuti ili ndi mphamvu zamagetsi pakati pa ma conductor (monga mkuwa) ndi insulators (monga galasi). Ma atomu ochepa akunja mu kapangidwe ka silicon amatha kusintha machitidwe ake, chifukwa chake kuyera kwa silicon ya semiconductor grade kuyenera kukhala kokwezeka modabwitsa. Kuyeretsedwa kochepa kovomerezeka kwa silicon yamagetsi ndi 99.999999%.

Izi zikutanthauza kuti atomu imodzi yokha yopanda silicon ndiyomwe imaloledwa pa maatomu mabiliyoni khumi aliwonse. Madzi akumwa abwino amalola mamolekyu 40 miliyoni omwe si amadzi, omwe amakhala ochepera 50 miliyoni kuposa silicon ya semiconductor-grade.

Opanga ma silicon opanda kanthu amayenera kusintha silicon yoyera kwambiri kukhala mawonekedwe abwino a kristalo imodzi. Izi zimachitika poyika kristalo wa mayi wosakwatiwa mu silicon yosungunuka pa kutentha koyenera. Pamene makhiristo aakazi atsopano ayamba kukula mozungulira kristalo wa mayi, silicon ingot imapanga pang'onopang'ono kuchokera ku silikoni yosungunuka. Njirayi ndiyochedwa ndipo ingatenge sabata. Silicon ingot yomalizidwa imalemera pafupifupi ma kilogalamu 100 ndipo imatha kupanga zowotcha zopitilira 3,000.

Zowondazo zimadulidwa kukhala magawo owonda pogwiritsa ntchito waya wabwino kwambiri wa diamondi. Kulondola kwa zida zodulira za silicon ndizokwera kwambiri, ndipo ogwira ntchito ayenera kuyang'aniridwa nthawi zonse, kapena ayambe kugwiritsa ntchito zida zopangira tsitsi lawo. Mau oyamba achidule opangira ma silicon wofewa ndi osavuta ndipo sakuyamikira zopereka za akatswiri; koma akuyembekezeka kupereka maziko a kumvetsetsa mozama za bizinesi ya silicon wafer.

Ubale wopereka ndi wofunikira wa zowotcha za silicon

Msika wa silicon wafer umayendetsedwa ndi makampani anayi. Kwa nthawi yayitali, msika wakhala mumgwirizano wosakhwima pakati pa kupezeka ndi kufunikira.

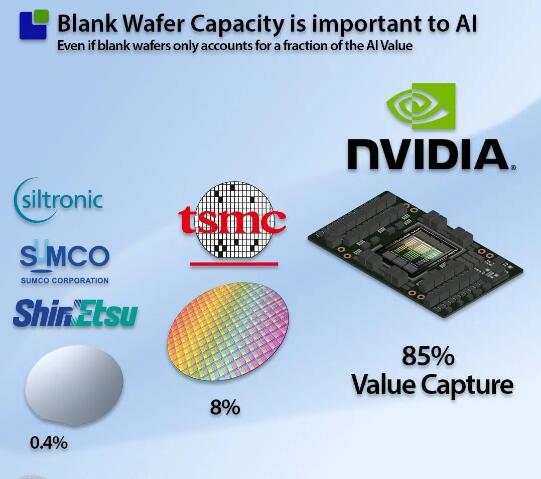

Kutsika kwa malonda a semiconductor mu 2023 kwapangitsa kuti msika ukhale wochulukirachulukira, zomwe zidapangitsa kuti zida zamkati ndi zakunja za opanga ma chip zikhale zapamwamba. Komabe, izi ndizochitika kwakanthawi. Msika ukayambiranso, makampaniwo posachedwa abwereranso m'mphepete mwa mphamvu ndipo ayenera kukwaniritsa zofunikira zomwe zabwera chifukwa cha kusintha kwa AI. Kusintha kuchokera ku zomangamanga zachikhalidwe za CPU kupita ku computing yofulumira kudzakhudza makampani onse, monga Komabe, izi zikhoza kukhala ndi zotsatira pa magawo otsika a makampani opangira semiconductor.

Zomangamanga za Graphics Processing Unit (GPU) zimafuna malo ochulukirapo a silicon

Pomwe kufunikira kwa magwiridwe antchito kumachulukirachulukira, opanga ma GPU ayenera kuthana ndi zoletsa zina kuti akwaniritse magwiridwe antchito apamwamba kuchokera ku ma GPU. Mwachiwonekere, kupanga chip chachikulu ndi njira imodzi yopezera ntchito zapamwamba, popeza ma elekitironi sakonda kuyenda mtunda wautali pakati pa tchipisi tosiyanasiyana, zomwe zimalepheretsa magwiridwe antchito. Komabe, pali malire othandiza kuti chip chikhale chachikulu, chomwe chimadziwika kuti "retina malire".

Malire a lithography amatanthawuza kukula kwakukulu kwa chip chomwe chingathe kuwonetsedwa mu sitepe imodzi mu makina a lithography omwe amagwiritsidwa ntchito popanga semiconductor. Kuchepetsa uku kumatsimikiziridwa ndi kukula kwamphamvu kwa maginito a zida za lithography, makamaka stepper kapena scanner yomwe imagwiritsidwa ntchito popanga lithography. Kwaukadaulo waposachedwa, malire a chigoba nthawi zambiri amakhala pafupifupi 858 masikweya millimita. Kuchepetsa kukula kumeneku ndikofunikira kwambiri chifukwa kumatsimikizira malo opitilira muyeso omwe atha kutsatiridwa pamtanda mukuwonekera kamodzi. Ngati chowotchacho chili chokulirapo kuposa malirewo, mawonetsedwe angapo adzafunika kuti apange mawonekedwe ophatikizika, zomwe sizingatheke kupanga zambiri chifukwa cha zovuta komanso zovuta za momwe mungayanitsire. GB200 yatsopano idzagonjetsa izi mwa kuphatikiza magawo awiri a chip ndi malire a kukula kwa tinthu kukhala silicon interlayer, kupanga gawo lapansi lopanda tinthu tating'ono lomwe ndi lalikulu kuwirikiza kawiri. Zolepheretsa zina ndi kuchuluka kwa kukumbukira ndi mtunda wa kukumbukira (ie memory bandwidth). Zomangamanga zatsopano za GPU zimathetsa vutoli pogwiritsa ntchito kukumbukira kwapamwamba kwambiri (HBM) komwe kumayikidwa pa silicon interposer yomwe ili ndi tchipisi ta GPU. Kuchokera pamalingaliro a silicon, vuto la HBM ndikuti gawo lililonse la silicon ndi lowirikiza kawiri la DRAM yachikhalidwe chifukwa cha mawonekedwe ofananira omwe amafunikira bandwidth yayikulu. HBM imaphatikizanso chip control logic mu stack iliyonse, ndikuwonjezera dera la silicon. Kuwerengera movutikira kukuwonetsa kuti dera la silicon lomwe limagwiritsidwa ntchito muzomanga za 2.5D GPU ndi 2.5 mpaka 3 kuchulukitsa kamangidwe kakale ka 2.0D. Monga tanena kale, pokhapokha ngati makampani opangira maziko akonzekera kusinthaku, mphamvu ya silicon wafer imatha kukhala yolimba kwambiri.

Kuchuluka kwamtsogolo kwa msika wa silicon wafer

Lamulo loyamba mwamalamulo atatu opangira semiconductor ndikuti ndalama zambiri zimafunika kuyikidwapo ngati pali ndalama zochepa. Izi ndichifukwa chakusintha kwamakampani, ndipo makampani opanga ma semiconductor amavutika kutsatira lamuloli. Monga momwe zasonyezedwera pachithunzichi, ambiri opanga zowotcha za silicon azindikira kukhudzika kwa kusinthaku ndipo achulukitsa pafupifupi katatu ndalama zawo zonse za kotala m'magawo angapo apitawa. Ngakhale kuti msika uli wovuta, izi zidakali choncho. Chosangalatsa kwambiri ndi chakuti izi zakhala zikuchitika kwa nthawi yaitali. Makampani a silicon wafer ali ndi mwayi kapena amadziwa zomwe ena sadziwa. Makina operekera semiconductor ndi makina anthawi omwe amatha kulosera zam'tsogolo. Tsogolo lanu likhoza kukhala la munthu wina. Ngakhale kuti nthawi zambiri sitipeza mayankho, pafupifupi nthawi zonse timapeza mafunso ofunika.

Nthawi yotumiza: Jun-17-2024